Sample Preparation & Sample Cleaning Equipment

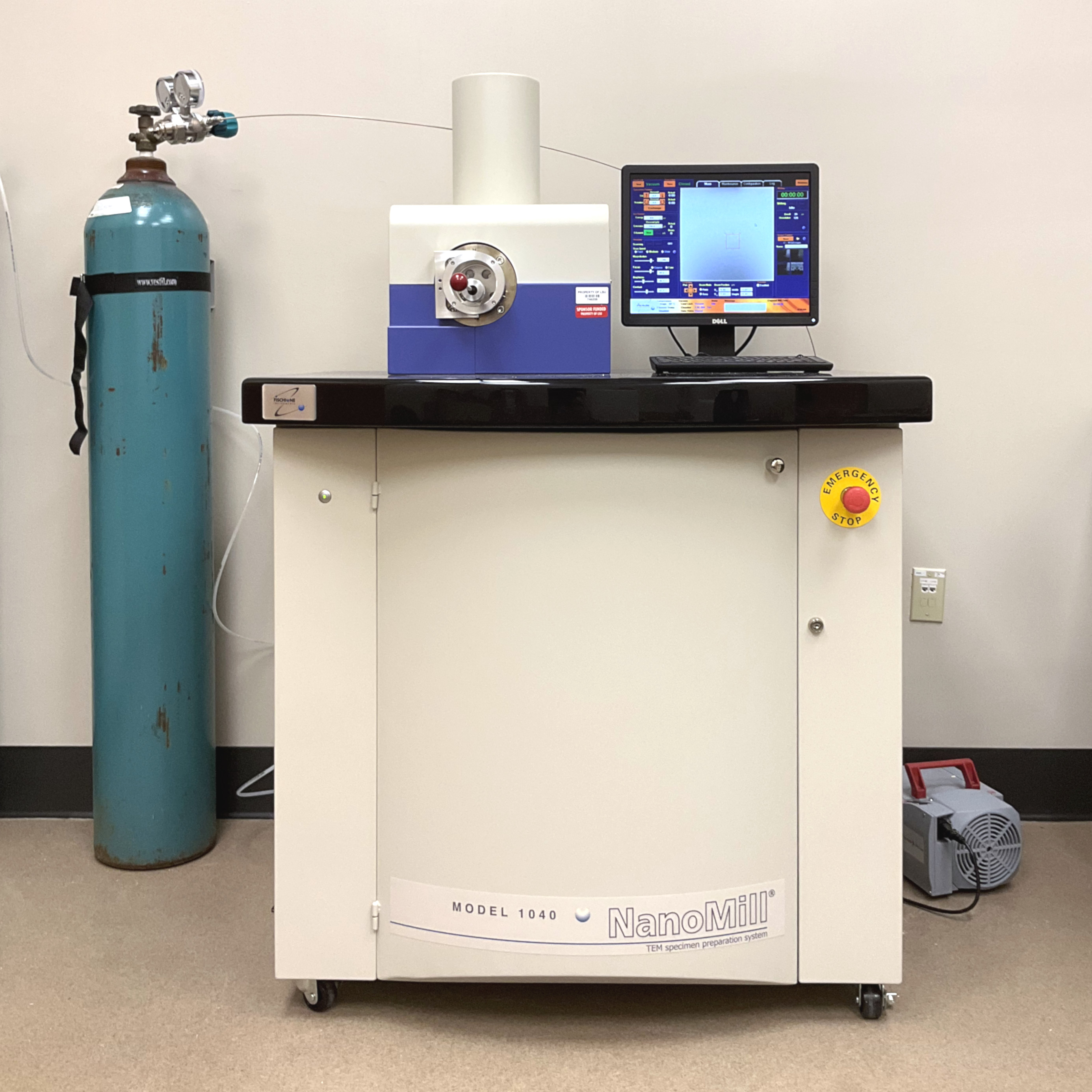

Fischione Instruments Model 1040 NanoMill®

The Model 1040 NanoMill® TEM specimen preparation system enables preparation of ultra-thin, high-quality specimens necessary for advanced transmission electron microscopy (TEM) imaging and analysis.

It provides a concentrated ultra-low-energy, inert argon ion beam for removal of amorphization, implantation or redeposition from specific areas of specimens produced by focused ion beam (FIB) milling. The system is also useful for the final thinning of conventionally prepared and FIB prepared TEM specimens.

- Beam energy ranges from 50 eV up to 2000 eV

- Variable emission current

- Beam size approx. 2 μm

- Beam can be either targeted at a specific area or scanned over the specimen’s surface

- Real-time view of the specimen using the secondary electron signal allows precise targeting

- Room temperature or liquid nitrogen-cooled stage (−175°C for up to 6 h)

- Milling angle range from -10° to +30°

- Oil-free, dry vacuum system

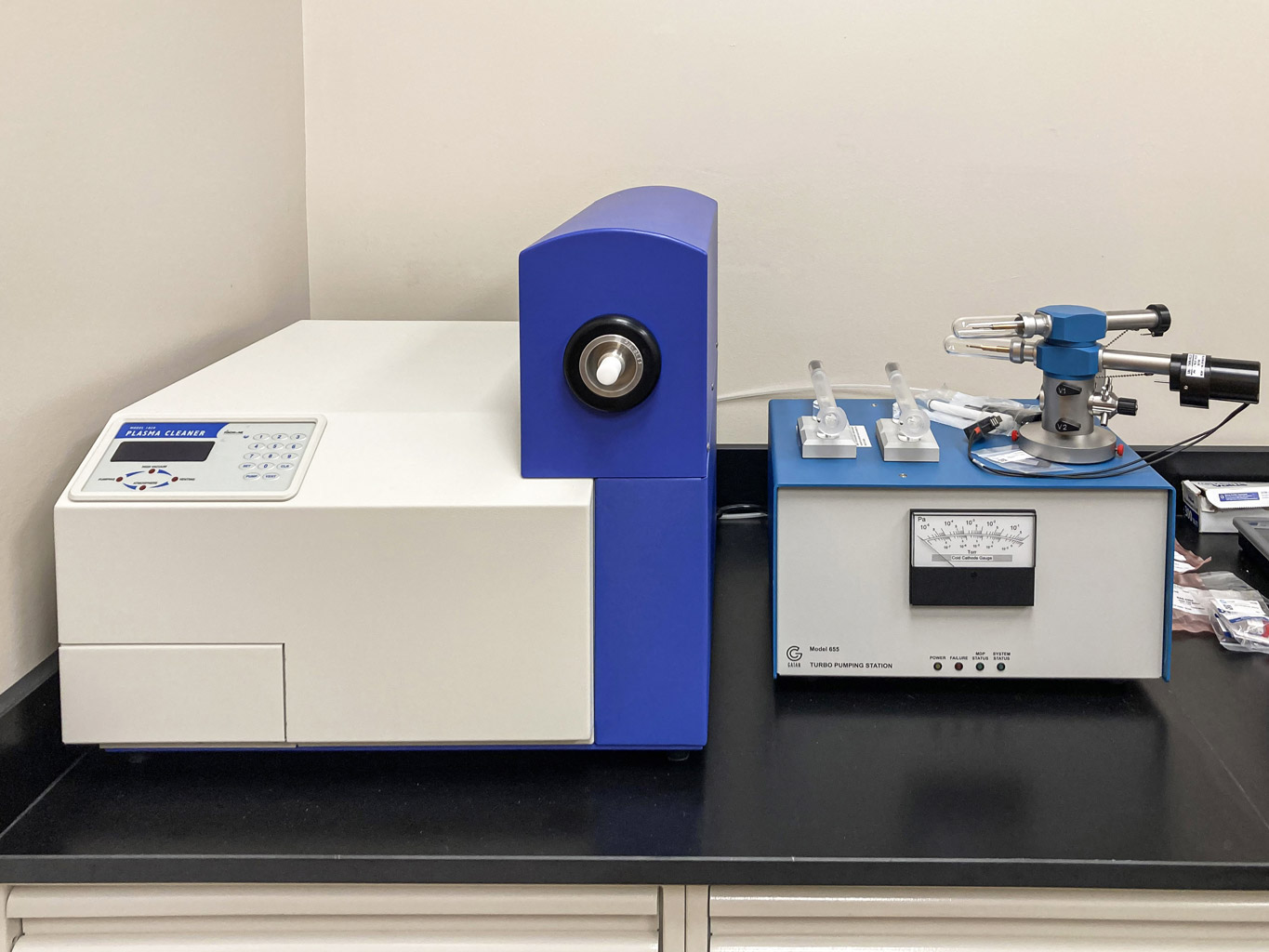

Fischione Instruments Model 1020 Plasma Cleaner

With the Model 1020 Plasma Cleaner specimens can be cleaned immediately before inserting them into the TEM.

Plasma cleaning removes existing carbonaceous debris from the specimen and also prevents contamination from occurring during TEM imaging and analysis.

The plasma is generated from a 25% oxygen, 75% argon gas mix.

Fischione Model 1020 Plasma Cleaner (left) and Gatan Turbo Pumping Station (right)

in Chemistry & Materials Building, Room 122A

Fischione Model 1020 Plasma Cleaner (left) and Gatan Turbo Pumping Station (right)

in Chemistry & Materials Building, Room 122A

Hitachi ZONETEM II Sample Cleaner

The ZONETEM II is used for the pretreatment of specimens to be observed by S/TEM.

The treatment mechanism is based on UV radiation (185 nm and 254 nm wavelengths), which breaks the chemical bonds of hydrocarbon contaminants in/on the specimen to react with active oxygen (to form H2O, CO or CO2). This will reduce the contamination of the specimen surface in and around the area of observation caused by exposure to the electron beam.

This method is especially useful for specimens which would otherwise oxidize in the Ar/O plasma of a plasma cleaner, e.g. for carbon based materials like graphene, and 2D materials like transition metal dichalcogenides.

Ports compatible with FEI and Jeol specimen holders.

Hitachi ZONETEM II Sample Cleaner in Chemistry & Materials Building, Room 122A

Hitachi ZONETEM II Sample Cleaner in Chemistry & Materials Building, Room 122A

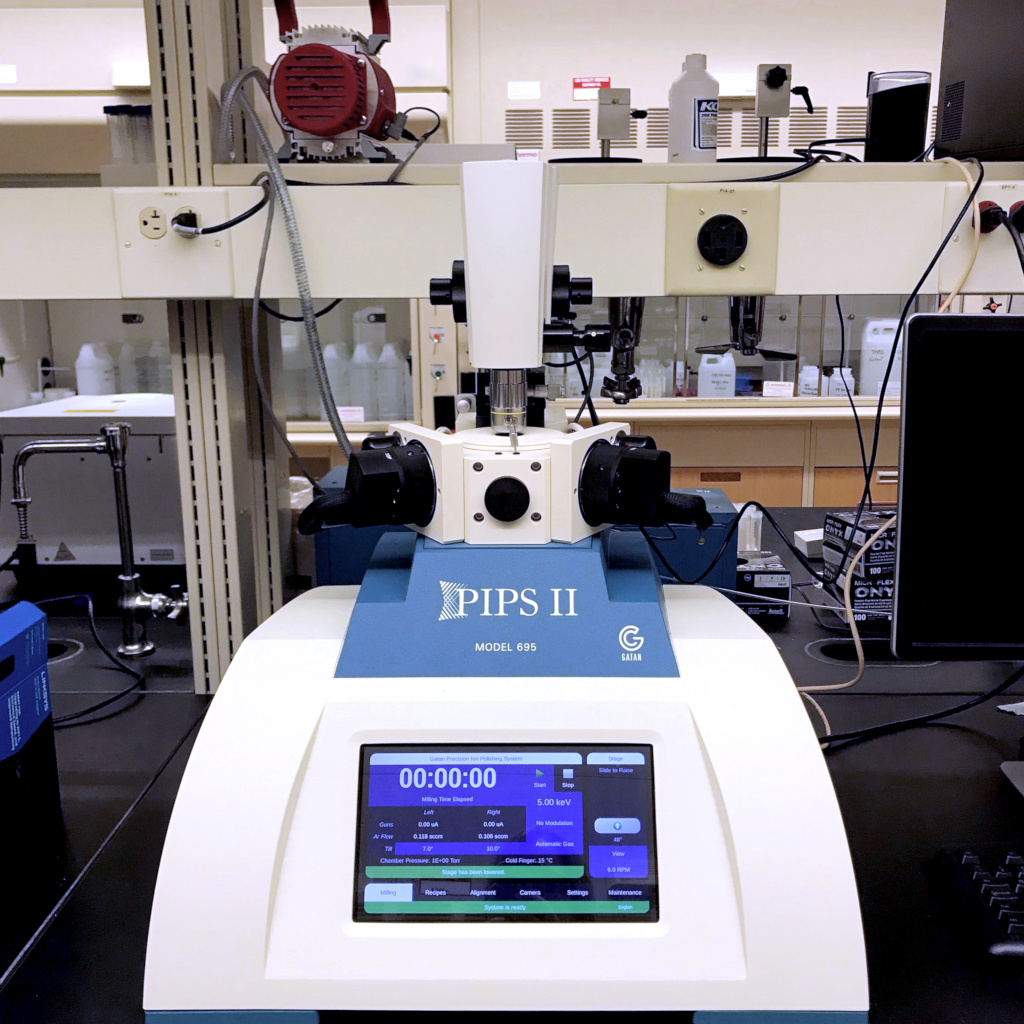

Gatan PIPS II Precision Ion Polishing System

Model 695 precision ion polishing system for TEM specimen preparation by broad ion beam milling with argon.

It can be used in combination with the Gatan Dimple Grinder or to polish FIB lift-out samples.

- X-Y stage for alignment of the Ar beam to region of interest on the sample

- Voltages as low as 100 V for fast and damage free preparation of FIB milled specimens

- Digital imaging and analysis in DigitalMicrograph®

- 10" color touch screen for display and control

- Accelerating voltage: 100 V – 8 kV

- Milling angle: -10° to +10°

- Ion current density peak: 10mA/cm2

- Sample size: 3 mm diameter disc

- Rotation speed: 1 – 6 rpm

- X, Y transition: ± 0.5 mm

Gatan PIPS II Precision Ion Polishing System in Chemistry & Materials Building, Room

168

Gatan PIPS II Precision Ion Polishing System in Chemistry & Materials Building, Room

168

ThermoFisher Scientifc Vitrobot Mk IV

To conserve protein samples in their most natural state for the investigation by TEM these samples are usually vitrified using liquid ethane. This process allows exposure to the electron beam under high vacuum without the sample drying out and is referred to as Cryo-EM.

The goal of this preparation process is to create an electron transparent film of amorphous/vitrified ice containing the protein sample, suspended across holes of typically 2–3 µm diameter within a 3 mm TEM specimen grid.

- Software controlled temperature (4 - 60°C)

- Software controlled humidity (up to 100% rH)

- Sample application through a side port with a pipette

- Software controlled blotting (1 - 16 actions)

- Entire process is controlled by a built in PC

- Leica EM ACE600 for glow discharge

Vitrobot setup in Chemistry & Materials Building, Room 162

Vitrobot setup in Chemistry & Materials Building, Room 162

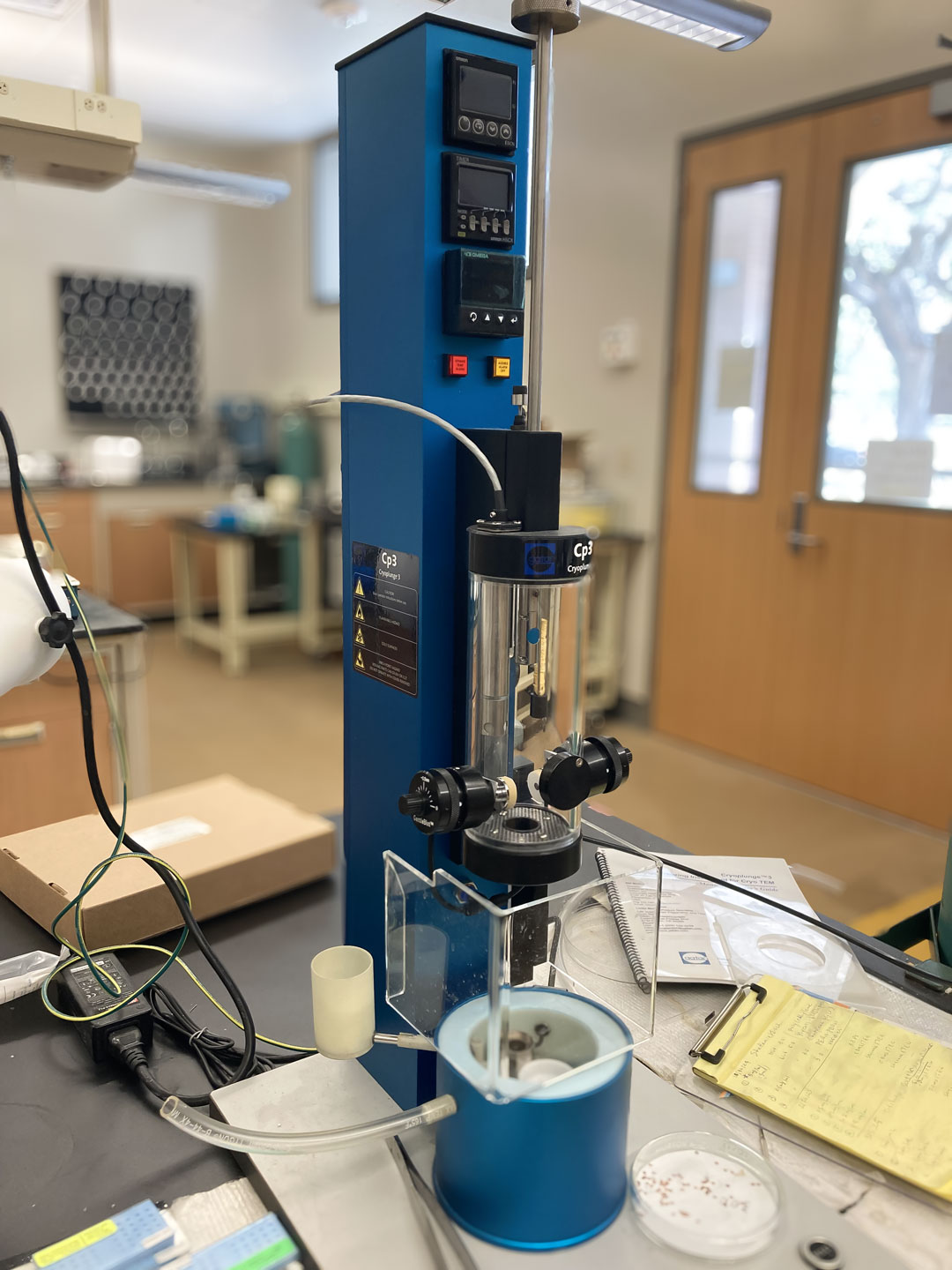

Gatan Cryoplunge™ 3 with GentleBlot™

The Gatan Cryoplunge™ 3 with GentleBlot™ is another (semi-)automatic vitrification device used to vitrify proteins for cryo-TEM.

- GentleBlot technology blotting for preparing frozen hydrated TEM specimens

- Ethane temperature controller

- Quick disconnect tweezers

- Protected environment

- Leica EM ACE600 for glow discharge

Cryoplunge™ 3 setup in Chemistry & Materials Building, Room 162

Cryoplunge™ 3 setup in Chemistry & Materials Building, Room 162

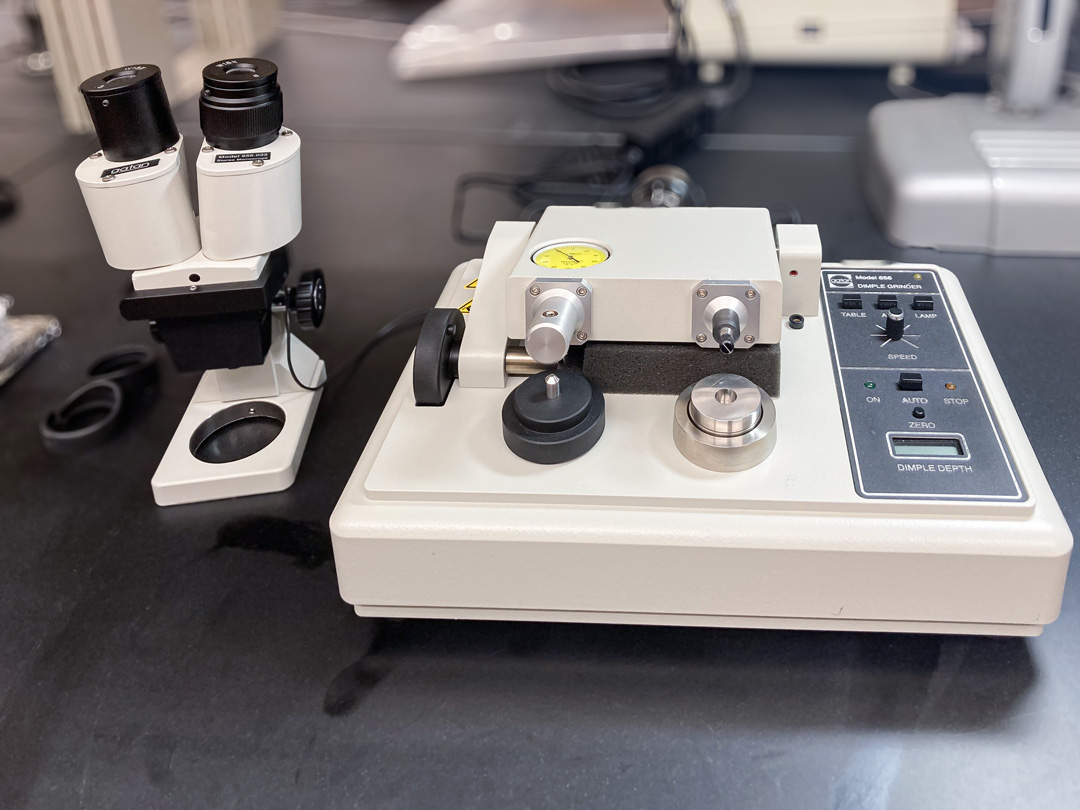

Gatan Model 656 Dimple Grinder

The dimple grinder is used to mechanically pre-thin a 3 mm TEM sample to near electron transparency to greatly reduce Argon ion milling times and uneven thinning.

- Large transparent areas

- Stronger specimen with a thick supporting rim to protect and strengthen the specimen after dimpling

- Accurate depth and thickness control

Gatan Dimple Grinder in Chemistry & Materials Building, Room 168

Gatan Dimple Grinder in Chemistry & Materials Building, Room 168

Fischione Instruments Model 1040 NanoMill® in Chemistry & Materials Building, Room

122A

Fischione Instruments Model 1040 NanoMill® in Chemistry & Materials Building, Room

122A